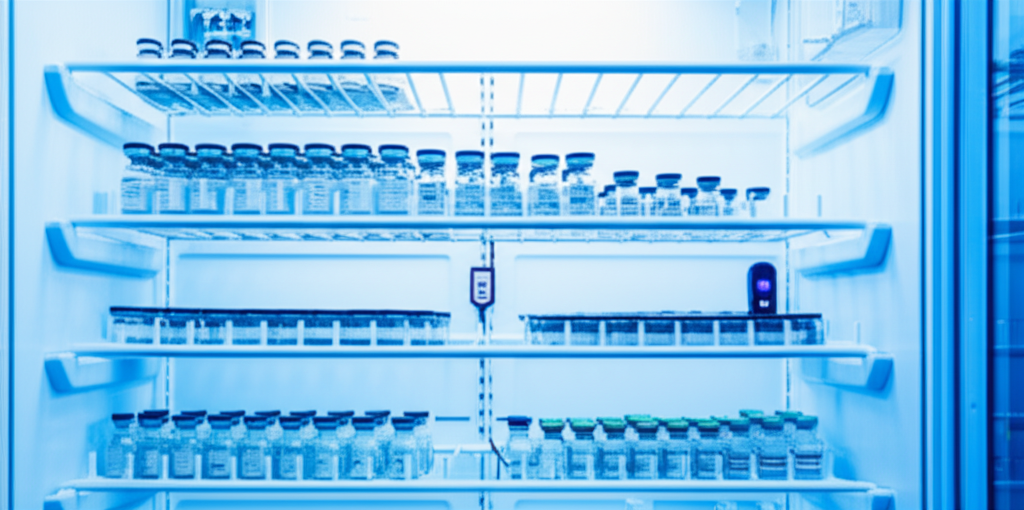

In the pharmaceutical industry, precise temperature and humidity monitoring of refrigerators, freezers, and storage areas is essential for ensuring medication safety and regulatory compliance. However, many pharmacies still rely on manual monitoring methods that are prone to human error, oversights, and delayed responses.

Steps in Manual Temperature Monitoring

A typical manual monitoring process involves:

- Reading thermometers on each refrigeration unit

- Recording temperatures manually in logbooks or spreadsheets

- Comparing readings against acceptable ranges (2–8°C for refrigerated drugs, -20°C for frozen items)

- Verifying humidity levels (typically 30–50% RH)

- Manually adjusting thermostat settings when needed

- Documenting corrective actions with time and cause

- Notifying supervisors of any critical deviations

Primary Limitations of Manual Systems

Human Error

Manual data entry is inherently prone to mistakes. Transcription errors, forgotten readings, and illegible handwriting can all compromise your compliance records.

Labor-Intensive Processes

Multiple refrigeration units require significant staff time for routine monitoring-time that could be better spent serving patients.

Delayed Detection

Temperature deviations that occur between scheduled checks may go unnoticed for hours, potentially compromising medication integrity.

No Real-Time Monitoring

Without continuous monitoring, you’re essentially flying blind between manual readings. Critical events can occur at any time.

Inconsistent Frequency

Staffing levels and workload variations lead to irregular monitoring schedules, creating gaps in your data.

Inaccurate Readings

Outdated or poorly calibrated equipment can provide false readings, giving a false sense of security.

Environmental Fluctuations

Humidity readings can vary significantly based on measurement location and timing, making manual readings unreliable.

No Automated Alerts

Perhaps most critically, manual systems cannot alert staff to after-hours incidents. A freezer failure at 2 AM on a Sunday won’t be discovered until Monday morning-often too late.

Documentation Burdens

The paperwork required for compliance creates administrative overhead and increases the risk of documentation gaps or errors.

The Cost of Complacency

Each of these limitations represents a potential compliance violation or product loss. In an industry where medication integrity directly impacts patient safety, manual monitoring simply cannot provide the protection your pharmacy needs.

A Better Approach

ATEK’s automated monitoring solutions provide:

- 24/7 continuous monitoring with instant alerts

- Automatic documentation for compliance reporting

- Real-time dashboards accessible from anywhere

- Elimination of human error in data collection

- Peace of mind knowing your medications are protected

Ready to move beyond manual monitoring? Contact ATEK to discover how automated solutions can protect your pharmacy’s inventory and simplify compliance.

![Securing your Laboratory During Extended Absences [Practical Guide]](/images/blog/securing-laboratory-absences.png)