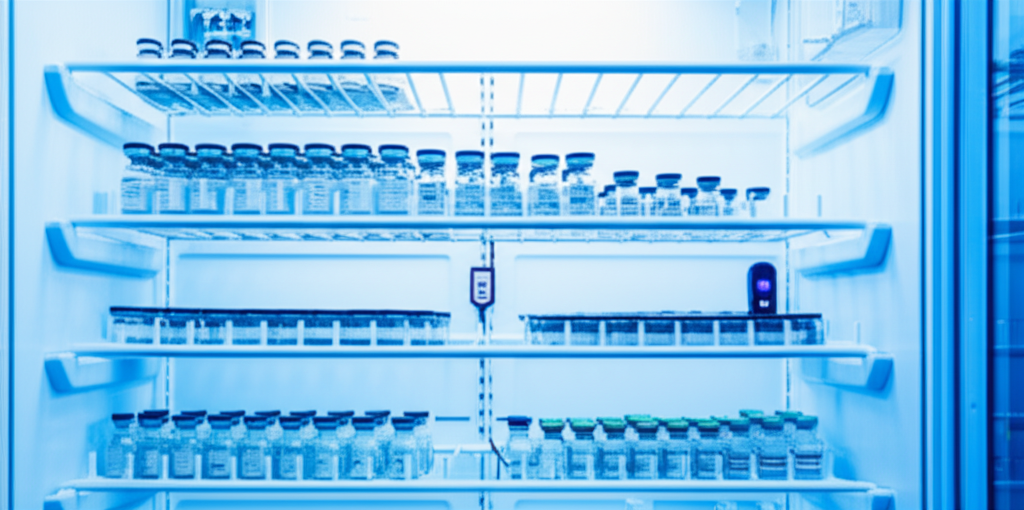

Refrigerators often experience significant temperature variations. These variations can come from several sources:

- Door opening — Each opening lets in ambient air

- Cooling cycle — The compressor activates and stops periodically

- Defrost cycle — The refrigerator temporarily heats up to eliminate frost

With a temperature monitoring system like ATEK’s, you can see all variations, and deviations must be documented.

Here are some tips to reduce temperature variations, helping to reduce the documentation workload for normal refrigerator operation.

Increasing Thermal Inertia

Thermal inertia is the physical capacity of a material to maintain its temperature.

A refrigerator works better and has more stable temperature when it’s full.

To increase thermal inertia, simply add water bottles to unused spaces in the refrigerator:

- Near the evaporator (at the top)

- On the bottom shelf

- In door compartments

- Around the edges of shelves

Preparing Water Bottles

Water bottles should be prepared as follows:

- Tint the water blue with food coloring to ensure no one is tempted to drink the liquid

- Add a small amount of rubbing alcohol to prevent bacterial growth in the water

This simple method allows you to:

| Benefit | Explanation |

|---|---|

| Stabilize temperature | Water absorbs temperature fluctuations |

| Reduce excursions | Fewer deviations during door openings |

| Decrease documentation | Fewer variations = fewer events to document |

| Protect products | Maintains constant temperature even during power outages |

Impact on Monitoring

With an ATEK monitoring system, you’ll notice:

- Smoother temperature curves

- Fewer alerts for normal variations

- Better protection during power outages

- Simplified documentation for audits

Conclusion

Increasing thermal inertia is a simple and economical solution to improve temperature stability in your refrigerators. By combining this technique with an automated monitoring system like ATEK, you optimize both product protection and the efficiency of your compliance documentation.

Need help optimizing your monitoring? Contact ATEK for an assessment of your needs.

![Securing your Laboratory During Extended Absences [Practical Guide]](/images/blog/securing-laboratory-absences.png)