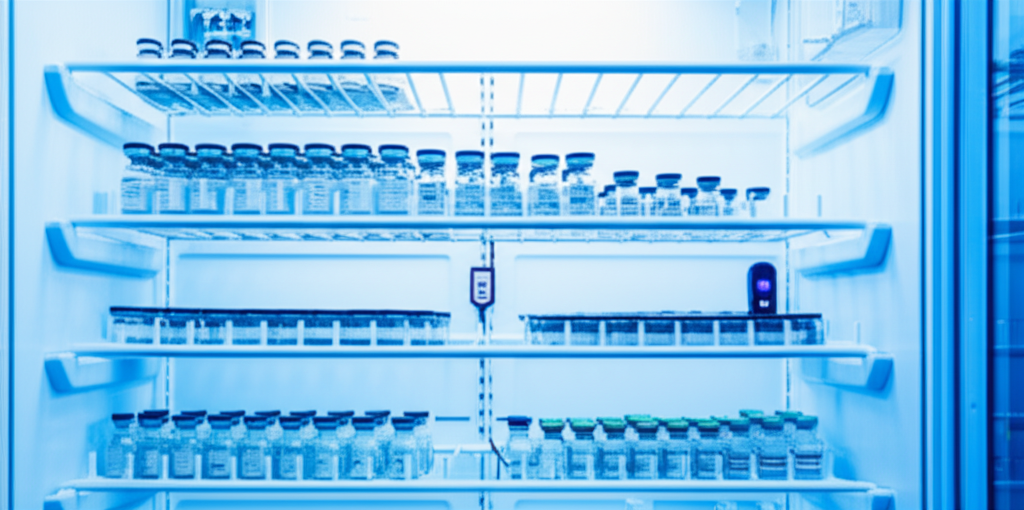

Mold growth in medical and pharmaceutical refrigerators represents a serious risk to stored product quality and regulatory compliance. Here is a comprehensive guide to prevent this problem.

Why Does Mold Develop?

Mold thrives under specific conditions:

- High humidity — Condensation and excessive moisture create a favorable environment

- Poor air circulation — An overloaded refrigerator prevents adequate circulation

- Organic residues — Uncleaned spills promote fungal growth

- Inadequate temperature — Fluctuations create condensation

Prevention Strategies

1. Maintain Stable Temperature

Temperature fluctuations cause condensation, creating a humid environment favorable to mold.

Recommendations:

- Use an ATEK monitoring system to detect variations

- Avoid opening the door too frequently

- Ensure the door seal is in good condition

2. Ensure Good Air Circulation

Recommendations:

- Don’t overload the refrigerator

- Leave space between products (minimum 2-3 cm)

- Don’t block circulation vents

- Follow spacing guidelines from the Vaccine Management Standards Guide

3. Clean Regularly

Recommended frequency:

- Weekly cleaning of interior surfaces

- Monthly deep cleaning

- Immediate cleaning of any spills

Recommended products:

- Water and baking soda solution

- Avoid harsh chemicals that can leave residues

4. Control Humidity

Recommendations:

- Use humidity absorbers if necessary

- Check the defrost system

- Ensure the drain is not blocked

5. Inspect Regularly

Checkpoints:

- Door seals (wear, mold)

- Hard-to-reach corners

- Grilles and vents

- Vegetable drawer and compartments

Warning Signs

Watch for these problem indicators:

| Sign | Action |

|---|---|

| Musty odor | Immediate inspection and cleaning |

| Black or green spots | Deep cleaning |

| Excessive condensation | Check temperature and seals |

| Wet products | Check humidity and circulation |

Impact on Compliance

The presence of mold can:

- Compromise the quality of stored products

- Result in observations during inspections

- Create health risks for staff

- Require costly decontamination

The Role of Monitoring

A monitoring system like ATEK can help prevent conditions favorable to mold by:

- Detecting abnormal temperature fluctuations

- Alerting on door faults (door left open)

- Providing trend data to identify recurring problems

- Documenting conditions for audits

Recommended Cleaning Protocol

Weekly Cleaning

- Remove expired or damaged products

- Wipe surfaces with baking soda solution

- Check door seals

- Clean spills

Monthly Cleaning

- Completely empty the refrigerator

- Clean all interior surfaces

- Disinfect seals and corners

- Check the drain

- Inspect grilles and vents

Conclusion

Preventing mold in medical and pharmaceutical refrigerators is essential for maintaining product quality and regulatory compliance. A combination of good maintenance practices, continuous monitoring, and rigorous cleaning protocols ensures an optimal storage environment.

Need help optimizing your monitoring? Contact ATEK for an assessment of your needs.

![Securing your Laboratory During Extended Absences [Practical Guide]](/images/blog/securing-laboratory-absences.png)