The scene takes place in February 2018. A supra-regional ultra-specialized university hospital is hesitating between two options for monitoring the temperatures of about forty refrigerators: a datalogger (data recorder) or an automatic temperature monitoring and management system.

One main constraint emerges from their specifications: selecting an economical, low-cost monitoring device.

At first glance, purchasing a datalogger seems like the quickest solution, but also the most effective and economical. However, the hospital is reluctant to consider the benefits of an automatic temperature monitoring system.

In the following article, ATEK offers a comparison highlighting the advantages and disadvantages between dataloggers and automatic data management and monitoring systems.

1. Regulatory Compliance

We know that dataloggers, integrated with rigorously applied management procedures and protocols, can achieve regulatory compliance as valid as with an automatic temperature management system. However, the difficulty with dataloggers is ensuring compliance with management procedures.

The reason is that with a datalogger, given the monthly compilation, it will only be possible to determine if products have been subjected to an unacceptable variation at the end of the month.

This semi-manual solution is not quite in the spirit of the standard. Indeed, monitoring standards require daily readings to ensure daily validation by a person in order to react quickly in case of deviation. Otherwise, products could have been given to patients since the non-compliance occurred (with or without consequences for their health).

Conversely, an automatic temperature management system greatly facilitates compliance management by automating processes. In a few clicks, it’s possible to visualize the entire refrigerator fleet, identify inappropriate temperatures, and generate reports.

2. Workload Related to Compliance Management

Dataloggers record data for 30 days. This system requires making a “round” once a month to retrieve dataloggers and transfer data.

This datalogger control and update operation is tedious work consisting of:

- Walking to each of the 40 refrigerators

- Annotating / labeling each datalogger with refrigerator information

- Installing new dataloggers

- Ensuring each new datalogger is functional

- Returning to the office

- Opening the computer

- Opening the transfer software

- Transferring data from the 40 dataloggers

- Writing deviation reports if necessary

- Renaming files with refrigerator names and dates

- Printing the 40 data reports

- Saving and archiving file copies

All these tedious tasks are susceptible to human error.

Additionally, several potential inconveniences arise:

- One of the responsible persons forgets to collect or is absent on collection day

- The computer on which transfers are made is updated and no longer accepts datalogger drivers

These are all situations that affect the accuracy of readings, not to mention the enormous loss of time and obvious risk of losing data.

With an automatic monitoring system like ATEK, all this is done automatically and seamlessly.

3. Alert System and Loss Prevention

Generally, with a datalogger, refrigerators are connected to the security station where security agents must contact designated managers in case of an alert.

In many institutions, security agents are few, especially in the evening. Frequently, while the agent makes their rounds, the monitoring console connected to the equipment is unattended for several dozen minutes. In this case, the alarm is only notified by the agent upon return, at the end of their round.

In hospitals, equipment such as refrigerators are secured. Security agents cannot access them and therefore cannot verify the state of a refrigerator that is alarming. When a manager is alerted, they must go on-site to check the refrigerator and transfer contents to another refrigerator if needed.

In sum, several hours can elapse between an alarm triggering and problem resolution. These delays often lead to losses.

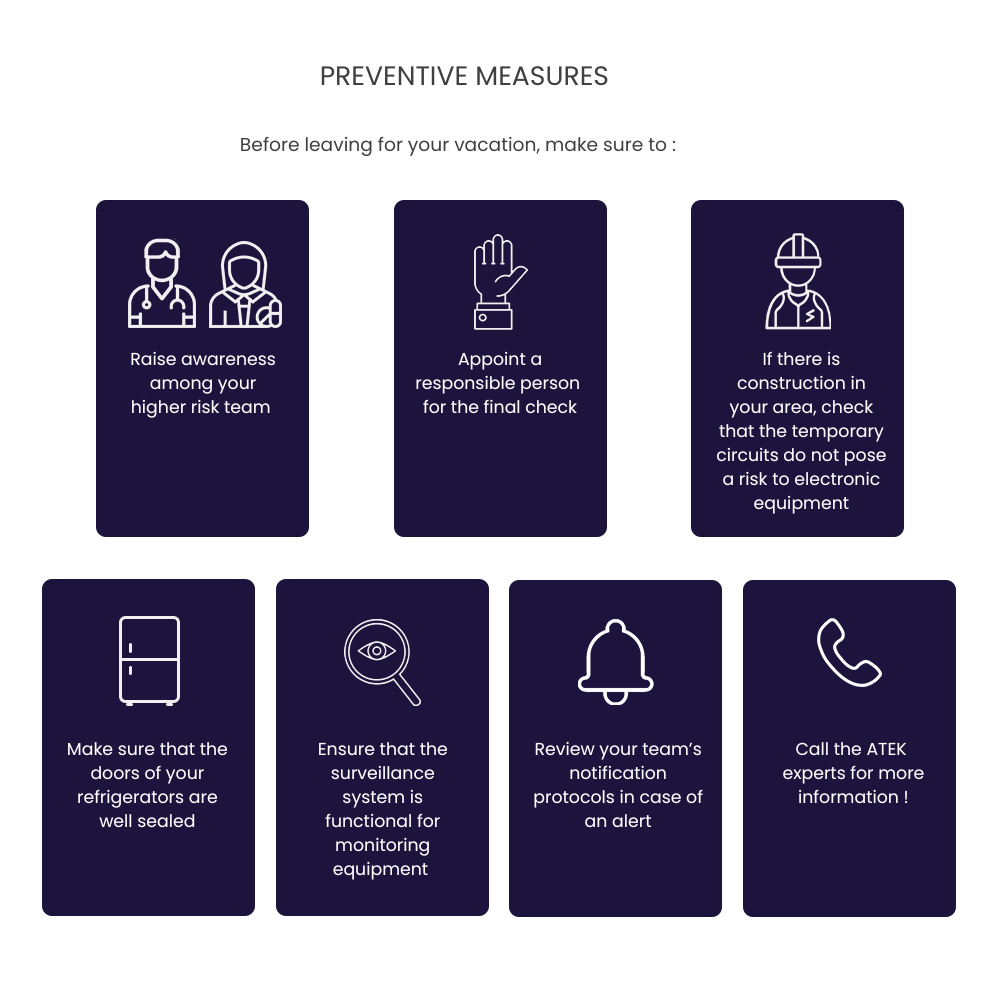

Prevention

With an automatic temperature monitoring and management system, it’s possible to see temperature trends on screen. These allow you to know and predict the behavior of a refrigerator or any other equipment. If, for example, a refrigerator seems unstable, it’s possible to immediately transfer products to a temporary refrigerator to prevent a problem.

Alarm and Notification Protocol

An automatic temperature monitoring and management system allows you to develop a “custom” notification protocol where alert notifications are made by phone, text, email, and pager. This protocol allows reaching multiple people simultaneously in a deferred manner. With access from any web browser, it’s possible to visualize refrigerator status and inhibit alarms remotely.

Conclusion: Invest Now or Postpone the Inevitable?

Nowadays, a pharmacist or technical assistant has many other things to do than focus on equipment temperature control. These responsibilities can now be better handled by machines, allowing considerable time savings for employees.

Even though an automated temperature management system appears more expensive than dataloggers, using a datalogger only defers the inevitable purchase of an automated system. Indeed, with specialized tools, the management cost including lost time and frustration related to datalogger use is quickly recouped. Moreover, temperature monitoring is standardized and configured upstream for all concerned departments.

An Automated System Meets 3 Essential Needs

| Need | Benefits |

|---|---|

| Regulatory Compliance | Accreditation Canada, Health Canada, OPQ, Vaccine Management Standards Guide, CAP, FDA, BNQ |

| Workload Reduction | Process automation, elimination of repetitive manual tasks |

| Loss Prevention | Advanced notification protocol, real-time alerts, rapid intervention |

It should also be noted that the increasingly strict requirements of regulatory entities should not be neglected. These are regulatory obligations that must be met sooner or later.

An automated temperature management system simplifies, secures, and eliminates paper document handling. It frees employees to focus on more qualified activities, allows remote management in case of alerts, and reduces loss risks.

Finally, an automated temperature management system meets present and future needs.